ENGLISH

Adhering to scientific and technological innovation for development, the company has established a research and development team led by many doctors, and built a 1000 square meters research and development laboratory; We have established a complete quality control system and management team, and applied for ISO9001 quality system certification and ISO14001 environmental management system certification.

Product Introduction

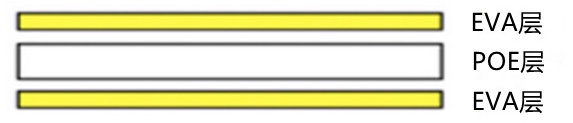

EPE isolation membrane is made of POE coated with EVA on both sides. Its structure is three-layer structure of E layer/POE film/E layer. The membrane can isolate the bus bar in the module, play an insulating role, and effectively prevent the short circuit of the bus bar in the module during use. Product characteristics: strong adhesion with EVA adhesive film, no wrinkle in the lamination, UV resistance, and breakdown resistance.

Structural composition of isolation membrane:

Layer E: Photovoltaic grade EVA resin, combined with anti ultraviolet, anti-aging agent and other additives, is used to have better weather resistance. P layer: Photovoltaic diaphragm is selected to ensure excellent mechanical and electrical properties.

The main model is BJ-E20.

Product technical parameters:

function | model | |

BJ-E20 | ||

thickness(mm) | 0.3-1.0 | |

width(mm) | ≤1400 | |

Roll length(m) | 150-350 | |

Area density deviation(%) | ±4 | |

Gram weight(g/m3) | ≧300 | |

tensile strength(MPa) | ≥100 | |

Elongation(%) | ≥110 | |

Water absorption(20℃、24h) | ≤5.0 | |

剥离强度(N/cm) | And glass | ≥60 |

And PET | ≥40 | |

Shrinkage(%) | direction(MD) | ≤2.0 |

broadwise(TD) | ≤1.5 | |

Volume resistivity(Ω·cm) | ≥1*1015 | |

Breakdown voltage strength (kv/mm) | ≥26 | |

UV aging △YI (120kwh/m2,1000 h) | ≤4 | |

Damp-heat aging △YI (85℃/85%,1000 h) | ≤4 | |

Lamination process:

4.1.Single-cavity lamination parameters

Product model | Lamination temperature(℃) | Vacuum pumping time(s) | Holding pressure | Holding time | ||

one paragraph | Section II | three-section | ||||

BJ-E20 | 145±2 | 360±30 | -75 | -45 | -20 | 660-720 |

4.2.Double cavity lamination parameters

Product model | First chamber temperature(℃) | Vacuum pumping time(s) | Holding pressure | Holding time | Second chamber temperature(℃) | Vacuum pumping time(s) | Holding pressure | Holding time | ||||

one paragraph | Section II | three-section | one paragraph | Section II | three-section | |||||||

BJ-E20 | 120±2 | 360±30 | -70 | -50 | -20 | 180±30 | 145±2 | 30±10 | -70 | -50 | -30 | 480±30 |

五、Storage and use:

1、Store in a cool and dry constant temperature room with temperature ≤ 30 ℃ and humidity ≤ 60%; The storage period of this product is six months; It is recommended to use it within three months;

2、Vacuum packaging, inner packaging 150-350 m/roll (except for special requirements);

3、The long-term stacking height of products is not easy to be too high, and it is better to store products below four layers to avoid bending and deformation caused by heavy pressure;

4、Do not damp the product. It is recommended to use the plastic film after opening the package or cutting it within 48 hours;

5、In order to avoid abnormal component lamination caused by static electricity, it is recommended to eliminate static electricity in the whole process of component production。

|

Previous:NO!

Next:NO! |

Return to list |